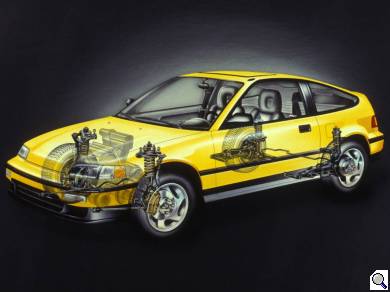

The 1988 CRX debuted alongside the fourth-generation Civic and was therefore among the first cars to use Honda's ingenious new four-wheel, double-wishbone suspension system. This race-proven suspension system is designed to provide some rather invigorating handling. The aerodynamically styled exterior also reduces wind resistance and improves gas mileage. The CRX is powered by an aluminium fuel-injected engine that promotes both performance and fuel efficiency. A low cowl line and slim pillars improve visibility. So you can see more of the world. It is also tuned for a comfortable, stable ride. By not even attempting to accommodate more than two people, the CRX was able to make exceptionally good use of its shortened Civic platform. There is plenty of front seat room for six footers, and the rear cargo area is truck-like in its capacity. CRX owners have been known to haul complete engines around in the commodious rear compartment. Light weight was obviously a design priority for the CRX, but as the years passed, marketing demands for a longer list of features and regulatory demands for passive restraints added weight and complexity.

To optimize the performance potential of the CRX, Honda engineers applied proven technology by integrating the four-wheel double wishbone suspension. This keeps the CRX stable and steady, no matter what the road surface.

Double-wishbone, or unequal length A-arm suspension, is a sophisticated design used in many racing and high performance cars. For a smooth ride even over sharp bumps, the front suspension system provides generous space for the wheels to move up and down. The double-wishbone geometry is nearly ideal, keeping the wheels virtually perpendicular to the road surface at all times.

Double-wishbone, or unequal length A-arm suspension, is a sophisticated design used in many racing and high performance cars. For a smooth ride even over sharp bumps, the front suspension system provides generous space for the wheels to move up and down. The double-wishbone geometry is nearly ideal, keeping the wheels virtually perpendicular to the road surface at all times.

Multi-control double-wishbone rear suspension also cancels out unwanted steering effects as the wheels encounter bumps, contributing the CRX's stable and steady ride.

The CRX rack-and-pinion steering has benefited from the new suspension design, which reduces friction and enhances road feel.

A special feature of the CRX Si is its variable-ratio steering, which gives the driver good steering response at normal driving speeds while reducing the effort needed for parking and tight turning.

The entire CRX line has ventilated front disc brakes. A large vacuum booster provides additional braking power, while this overall braking system design gives added resistance to brake fade.

The CRX Si is powered by a 105 horsepower, all-aluminium, 16-valve single overhead cam, programmed fuel-injection 1.6 litre engine. Four valves per cylinder derived from Honda's Formula 1 racing experience.

For the CRX engines, Honda derived a new simple mechanism. It actuates the four valves with a single overhead camshaft, yet provides the benefit of a double overheard camshaft arrangement. This allows for a more compact and lighter engine.

The 'pentroof' combustion chambers with centrally located spark plugs are ideal for powerful, efficient combustion. Four valves per cylinder allow the engine to induct air and fuel and expel exhaust with minimum resistance.

In order to save weight and dissipate heat, both cylinder block and head are made of aluminium alloy. The cylinder sleeves are steel for added strength and long life. Reduced engine weight pays off in many ways: lower fuel consumption, easier steering and more responsive handling.

All CRX models utilize inertia-axis engine mounts along the engine's axis of rotation (above the crankshaft centreline) to absorb vibration. This gives less noise and vibration inside the car.

Two versions of Honda's own PGM-FI are used by the 1988 CRX. Multi-Point Fuel Injection is on both the CRX HF and CRX Si, while the CRX utilizes Dual-Point Fuel Injection System.

Both fuel management systems (PGM-FI) utilize sensors and digital computer to inject the exact measure of fuel needed at precisely the right instant.

The Dual-Point PGM-FI System standard on the CRX uses two injectors to feed the fuel into the throttle body. Benefits are increased performance and engine response, with precise emission control.

The new chassis and power train engineering made it possible to give the CRX a significantly lower hood. By incorporating the double wishbone front suspension and compact engine layout, this low hood design was accomplished. Low-profile headlights and nearly flush windows also contribute to the CRX's and CRX Si's coefficient of drag (Cd) of 0.30. And to the CRX HF's rating (Cd) of 0.29.

Interior space benefits from the combination of body, chassis, suspension and power train engineering. For example, the double wishbone suspension allows for the floor pan to lower than the previous models. The result is more room for people, and a cargo capacity of 23.2 cubic feet.

Standard on all CRXs is a 5-speed manual transmission. The transmission ratios for each model have designed to take full advantage of the engine's torque characteristics. Higher gearing for the economy minded CRX HF and sportier gears for the CRX and performance-driven CRX Si.

The 4-speed automatic transmission comes with lockup torque converter. The new computer-controlled lockup torque converter 'decides' when to engage this fuel-saving feature for best fuel economy smoothness.

ModernRacer.com © 2004